Fluid Tech Systems is a premier manufacturer, supplier, and exporter of high-performance External Gear Pumps in India. With over 35 years of industry expertise, we provide ISO-certified solutions designed for precision, durability, and optimal operational efficiency. Our gear pumps are widely trusted across diverse industrial sectors for their consistent performance and long-term reliability.

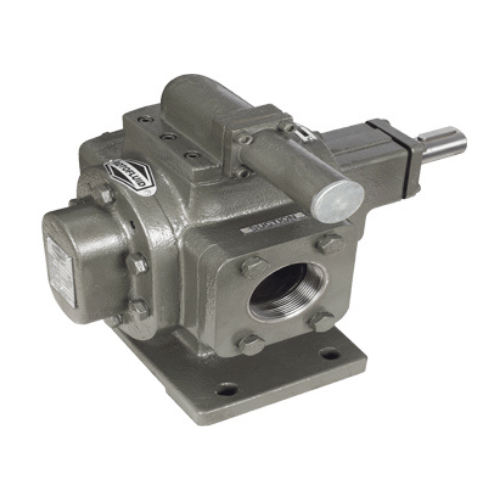

As a trusted External Gear Pump Manufacturer, we provide high-quality, robust, and precisely engineered external gear pumps designed to deliver reliable performance in demanding industrial environments. Manufactured using premium-grade materials and advanced machining technology, our external gear pumps are known for their accuracy, efficiency, and long service life. An External Gear Pump operates on the positive displacement principle. It consists of two external gears rotating in opposite directions within a tightly machined housing. As the gears unmesh on the inlet side, a vacuum is created, allowing fluid to be drawn into the pump chamber. The fluid is then carried around the periphery of the gears and discharged on the outlet side as the gears re-engage, generating continuous flow and stable pressure.

An External Gear Pump is a positive displacement pump that uses two externally meshed gears to transfer fluid efficiently and consistently. These pumps are widely used in industrial applications where precise flow control, high pressure handling, and long service life are required. As a leading External Gear Pump Manufacturer, we design and manufacture pumps that deliver superior performance, minimal leakage, and excellent durability under demanding operating conditions.

The External Gear Pump's positive displacement mechanism ensures a precise and continuous flow, making it ideal for transferring low to high-viscosity fluids. The tight internal clearances between gears and housing minimize slip, enhance volumetric efficiency, and maintain stable pressure even under heavy-duty industrial conditions. This level of precision engineering allows our pumps to deliver smooth, pulse-free fluid transfer with exceptional reliability.

| Part | Material For FTNX | Material For FTBX |

|---|---|---|

| Pump Body | CI/CS | CI/CS |

| Front Cover | CI/CS | CI/CS |

| Back Cover | CI/CS | CI/CS |

| Gland Cover | CI/CS | CI/CS |

| Rotor/Stator Shaft | EN-19 | EN-19 |

| Gear | EN-24/EN-353 | EN-24/EN-353 |

| Needle/Bush Bearing | INA/IKO [Japan] | Non- Ferrous |

| Wear Plate | Non- Ferrous | Non- Ferrous |

| Sealing | "GFO" Pack Teflon / Mech. Seals | "GFO" Pack Teflon / Mech. Seal |

| R.V. Housing | Mild Steel | Mild Steel |

| R.V. Piston | EN-8 | EN-8 |

| R.V. Spring | Spring Steel | Spring Steel |

| R.V. AD. Screw | EN-8 | EN-8 |

| Key | EN-8 | EN-8s |

| Hex - Bolt | Mild Steel | Mild Steel |

| Model FTNX/FTBX | Suction & Delivery Size | Capacity at 1440 RPM | ||

|---|---|---|---|---|

| LPM | US GPM | M/hr | ||

| 050-S | "" x "" | 05.00 | 1.32 | 0.30 |

| 050-M | "" x "" | 8.33 | 2.21 | 0.5 |

| 050-L | "" x "" | 16.00 | 04.42 | 1.00 |

| 100-S | 1" x 1" | 25.00 | 06.60 | 1.50 |

| 100-M | 1" x 1" | 33.32 | 08.80 | 2.00 |

| 100-L | 1" x 1" | 41.65 | 11.00 | 2.50 |

| 125-S | "1" x "1" | 50.00 | 13.25 | 3.00 |

| 125-M | "1" x "1" | 60.00 | 16.66 | 3.60 |

| 125-L | "1" x "1" | 83.00 | 22.00 | 5.00 |

| 150-S | "1" x "1" | 100.00 | 26.50 | 6.00 |

| 150-M | "1" x "1" | 125.00 | 33.00 | 7.50 |

| 150-L | "1" x "1" | 150.00 | 39.75 | 9.00 |

| 200-S | "2" x "2" | 166.60 | 44.16 | 10.00 |

| 200-M | "2" x "2" | 200.00 | 53.00 | 12.00 |

| 200-L | "2" x "2" | 250.00 | 66.25 | 15.00 |

| 250-S | "2" x "2" | 300.00 | 79.50 | 18.00 |

| 250-M | "2" x "2" | 333.00 | 83.33 | 20.00 |

| 250-L | "2" x "2" | 350.00 | 92.75 | 21.00 |

| 300-S | 3" x 3" | 400.00 | 106.00 | 24.00 |

| 300-M | 3" x 3" | 450.00 | 119.00 | 27.00 |

| 300-L | 3" x 3" | 600.00 | 159.00 | 36.00 |

| 400-S | 4" x 4" | 700.00 | 185.50 | 42.00 |

| 400-M | 4" x 4" | 800.00 | 212.00 | 48.00 |

| 400-L | 4" x 4" | 900.00 | 238.50 | 54.00 |

Our External Gear Pumps are widely used for handling:

Industries Served

An external gear pump is a type of positive displacement pump that uses two meshing gears to move fluid. One gear is driven (usually by a motor), and it turns the other gear, creating a vacuum that draws fluid into the pump and pushes it out on the discharge side.

An external gear pump works by using two meshing gears to draw fluid in and push it out. As the gears rotate, they create a space on the inlet side that pulls in liquid. This liquid is then carried around the casing in the spaces between the gear teeth and discharged on the outlet side when the gears mesh again.

External gear pumps offer high efficiency, compact size, and the ability to handle a wide range of fluid viscosities. They also provide a smooth, pulse-free flow, making them suitable for precision metering applications. Additionally, they are known for their durability and reliability in demanding industrial environments.

Regular maintenance for an external gear pump primarily involves ensuring proper lubrication, monitoring fluid quality, inspecting for leaks, and replacing worn parts.