The Fuel Injection Internal Gear Pump is engineered for accurate fuel delivery, offering dependable performance and high efficiency. Its compact, robust construction ensures seamless integration across a wide range of applications. Featuring a precision-engineered gear mechanism, the pump delivers smooth fuel injection with minimal pulsation, enhancing combustion efficiency. Its self-priming design enables quick and reliable suction, reducing startup delays and improving operational readiness. Built to withstand high pressures, the pump promotes fine fuel atomization for better engine performance. Durable, wear-resistant components extend service life while lowering maintenance requirements. Consistent fuel flow ensures stable engine operation, reducing fuel consumption and overall running costs. This makes the pump a reliable, cost-effective choice for industries that demand precise and efficient fuel injection systems.

Fluid Tech Systems, based in Ahmedabad, is a renowned manufacturer, supplier, and exporter of Fuel Injection Internal Gear Pumps (FIG). Engineered for high-efficiency performance, these pumps deliver precise fuel injection across a wide range of industrial applications. Known for their robust construction and long-lasting reliability, FIG pumps from Fluid Tech Systems require minimal maintenance while ensuring consistent operation. Backed by years of industry experience and a strong commitment to quality, the company has earned a reputation as a trusted name in the pump manufacturing sector. Serving both domestic and global markets, Fluid Tech Systems is dedicated to timely delivery and outstanding customer support.

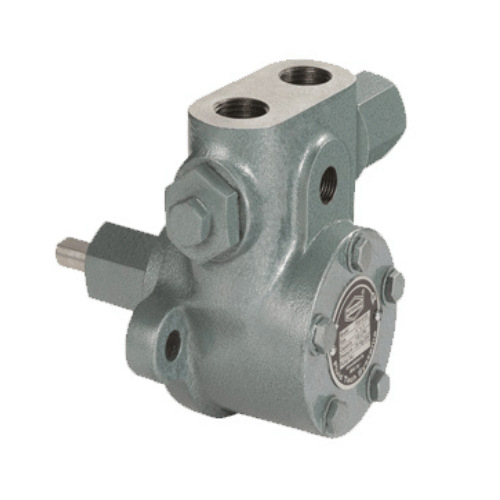

Fluid Tech Systems presents the ROTOFLUID Model FIG, a high-precision fuel injection internal gear pump designed for fuel injection, burner applications, and LDO pumping. Constructed from graded cast iron, this pump features nitrided gears and a shafted rotor, ensuring enhanced performance with tight tolerances for long service life.

The flange-mounted, self-priming design generates maximum vacuum, determined by the cavity between the gear teeth. Its modified tooth profile ensures accurate capacity within the pressure range. Designed to handle liquids up to 500 CST viscosity and temperatures up to 200°C, the pump utilizes a mechanical seal for zero leakage.

Suction and delivery connections are available in 3/8", 1/2", 3/4", and 1" sizes, with a capacity range from 60 LPH to 6000 LPH and operating pressures up to 35 kg/cm². For continuous duty, the recommended maximum pressure is 30 kg/cm². The pump operates at 2800 RPM, providing approximately double the capacity under normal conditions. It can run in both clockwise and counterclockwise directions, offering flexibility based on operational requirements.

| Part | Material For FIG |

|---|---|

| Body | IIS.210 FG 220 C.I. Grade |

| Eccentric | IIS.210 FG 220 C.I. Grade |

| Idler Gear | SAE-8620 |

| Rotor shaft | SAE-8620 |

| Sealing | Mechanical seal |

| Piston | EN-8 |

| Adjusting Screw | EN-8 |

| Spring | Spring Steel |

| Model | Capacity in LPH at 1440 RPM | Suction & Delivery Size | Motor HP | |

|---|---|---|---|---|

| LPM | US GPM | |||

| FIG-S6 | 60 | 3/8" x 3/8" | 0.25 | 1.00 |

| FIG-S9 | 90 | 3/8" x 3/8" | 0.25 | 1.00 |

| FIG-S12 | 120 | 3/8" x 3/8" | 0.25 | 1.00 |

| FIG-A15 | 150 | 1/2" x 1/2" | 0.25 | 1.50 |

| 1.50 | 300 | 1/2" x 1/2" | 0.25 | 1.50 |

| FIG-A45 | 450 | 1/2" x 1/2" | 0.25 | 2.00 |

| FIG-A60 | 600 | 1/2" x 1/2" | 0.25 | 2.00 |

| FIG-B100 | 1000 | 3/4" x 3/4" | 0.75 | 3.00 |

| FIG-B150 | 1500 | 3/4" x 3/4" | 0.75 | 3.00 |

| FIG-B200 | 2000 | 3/4" x 3/4" | 0.75 | 5.00 |

| FIG-B250 | 2500 | 3/4" x 3/4" | 0.75 | 5.00 |

| FIG-C300 | 3000 | 1" x 1" | 1.50 | 7.50 |

| FIG-C450 | 4500 | 1" x 1" | 1.50 | 10.0 |

| FIG-C600 | 6000 | 1" x 1" | 1.50 | 15.0 |

A Fuel Injection Gear Pump is a positive displacement pump used in fuel systems to supply pressurized fuel to the injection system of an engine. It uses intermeshing gears to move fuel from the tank to the fuel injectors at a precise pressure and flow rate, ensuring proper combustion and engine performance.

A fuel injection internal gear pump works by trapping and displacing fluid between the teeth of two rotating gears, one internal and one external, housed within a casing. As the gears rotate, they create a suction that draws fuel into the pump and then, as they mesh again, forces the fuel out under pressure to the engine's fuel injectors.

A Fuel Injection Internal Gear Pump is a type of positive displacement pump that provides precise, smooth, and consistent fuel delivery to injection systems.

Regular maintenance for a fuel injection internal gear pump includes ensuring proper lubrication, regular inspections, and keeping the pump clean. Specifically, this involves checking and replenishing grease in bearings, inspecting for wear or damage, and cleaning the pump and motor.

Fuel Injection Internal gear pumps can handle a wide range of fuels including: Diesel, Biodiesel, Fuel oil, Kerosene, Light lubricants.