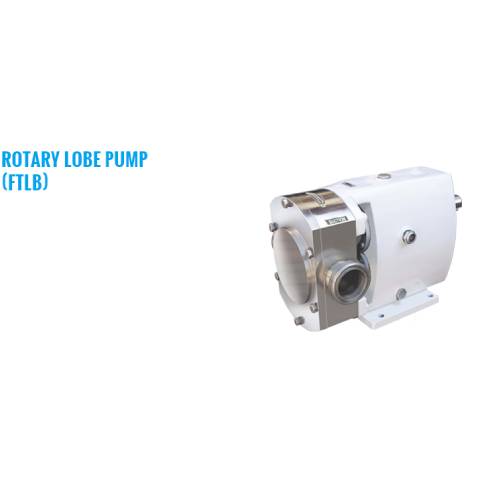

As a trusted Rotary Lobe Pump Manufacturer, we offer high- performance pumps designed for hygienic and industrial fluid handling applications. Rotary lobe pumps are positive displacement pumps known for gentle product handling, consistent flow, and excellent efficiency.

Our rotary lobe pumps are ideal for transferring viscous, shear-sensitive, and solid-laden fluids without damaging the product structure. These pumps are widely used in food, pharmaceutical, chemical, cosmetic, and biotechnology industries where cleanliness, reliability, and precision flow control are essential.

A rotary lobe pump is a positive displacement pump that uses two or more lobes rotating inside a casing to move fluid from the inlet to the outlet. The non-contacting lobes create sealed cavities, allowing smooth and pulsation-free flow while maintaining product integrity. Due to its hygienic design and easy cleanability, rotary lobe pumps are commonly used in sanitary and process industries.

The rotary lobe pump operates by rotating lobes that trap fluid between the lobes and the pump casing. As the lobes rotate, fluid is transferred from the suction side to the discharge side without internal contact, reducing wear and contamination. This ensures consistent flow and long service life even in demanding applications.

| Part | Material |

| Pump Chamber | ss - 316 |

| Tri-Lobe Rotor | ss - 316 |

| Top Cover | ss - 316 |

| Shaft | ss - 316 |

| Shaft Seal | Mech. Seal |

| Gear | EN - 24 |

| Casing | CI |

| Back Cover | CI |

| Bearing Spaler | CI |

| Bearing | SKF |

| el | Sction & Delivery | Displacemen@ 100 RPM | Max.Speed (RPM) | Pressure (kg/cm2) | Weight (Kg.) | ||

| LPM | US GPM | Horizontal Porting | Vertical Porting | ||||

| FTLB - 100S | 1" | 5 | 1.4 | 1000 | 7 | 15 | 16 |

| FTLB - 100L | 1" | 8 | 2.25 | 1000 | 7 | 17 | 18 |

| FTLB - 150S | 1½" | 12 | 3.38 | 1000 | 7 | 28 | 30 |

| FTLB - 150L | 1½ | 18 | 4.78 | 1000 | 7 | 30 | 31 |

| FTLB - 200S | 2" | 26 | 7.03 | 1000 | 7 | 52 | 55 |

| FTLB - 200L | 2" | 38 | 10.15 | 1000 | 7 | 55 | 58 |

| FTLB - 250S | 2½" | 55 | 14.64 | 1000 | 7 | 104 | 110 |

| FTLB - 250L | 2½" | 79 | 20.87 | 1000 | 7 | 109 | 115 |

| FTLB - 300S | 3" | 116 | 30.65 | 600 | 7 | 150 | 150 |

| FTLB - 300L | 3" | 175 | 44.39 | 600 | 7 | 158 | 158 |

| FTLB - 400S | 4" | 261 | 68.70 | 500 | 7 | 258 | 258 |

| FTLB - 400L | 4" | 354 | 93.26 | 500 | 7 | 264 | 264 |

A Rotary Lobe Pump is a uses rotating lobes (typically two or more) to move fluids through the pump chamber. The non-contacting lobes create continuous suction, making the pump ideal for viscous, shear-sensitive, or hygienic fluid transfer applications.

The pump has two lobes that rotate in opposite directions. As the lobes turn, they create expanding cavities on the inlet side, drawing in fluid. The fluid is then trapped between the lobes and the casing and transported to the discharge side. The lobes do not touch, allowing smooth and low-shear flow.

Gentle handling of sensitive or shear-prone fluids.

Self-priming and reversible flow direction.

Handles solids without damage.

Suitable for hygienic applications (CIP/SIP compatible).

High volumetric efficiency and low pulsation.

Easy to clean and maintain.

Yes. Rotary lobe pumps can handle soft or fragile solids like fruit chunks, curd, or viscous slurries without damaging the product or the pump.